|

CONTROL CHARTName:

For each of the supported control charts, limits have been determined for signaling when a response is "out of control". That is, if the points on the control chart are within the control limits, the data is considered "in control". When a point is outside these control limits, the data is considered "out of control" and the process should be examined to determine the cause. In developing the control limits, an effort is made to balance quick detection while minimizing "false positives" (i.e., signaling that a process is out of control when it is in fact still in control). Quick detection is desired to minimize the number of potentially bad units produced. Minimizing false positives is desired since shutting down the process can result in unnecessarily lost production (and possibly significant cost). The mean control chart is the most commonly used control chart for detecting a change in location. The CUSUM and EWMA charts were developed to detect small shifts of location. The standard deviation control chart and range control chart are the primary control charts for detecting a change in the variability of a process. Typically, the data for control charts is divided into batches (sub-groups) and the appropriate statistic is computed and plotted for each sub-group. The MOVING control charts are used for the case when the data are not divided into sub-groups. The ISO control chart is a variant of control charts used in the ISO 13528 standard for proficiency studies for multiple rounds. There is separate documentation for the mean, standard deviation, range, cusum, ewma, and the various proportion and counts control charts. This documentation may contain more details for that specific type of control chart. The control chart consists of:

In addition, horizontal lines are drawn at the mean (i.e., the mean of the means, ranges, standard deviations, or other appropriate statistic) and at the upper and lower control limits.

where <stat> is one of XBAR (or MEAN), R (or RANGE), S (or SD), CUSUM, or EWMA; <y> is the response variable; <x> is a variable containing the sub-group identifications; and where the <SUBSET/EXCEPT/FOR qualification> is optional. Enter one of MEAN, RANGE, S, CUSUM, or EWMA to specify what type of control chart to generate.

where <stat> is one of AVERAGE, RANGE, or SD; <y> is the response variable; and where the <SUBSET/EXCEPT/FOR qualification> is optional.

where <y> is the response variable containing the number of defectives for each sub-group; <size> is a variable containing the sample size for each sub-group; <x> is a variable containing the sub-group identifications; and where the <SUBSET/EXCEPT/FOR qualification> is optional. If P is specified, then the percentage of defectives is plotted. If NP is specified, then the number of defectives is plotted.

where <y> is the response variable containing the number of defectives for each sub-group; <x> is a variable containing the sub-group identifications; and where the <SUBSET/EXCEPT/FOR qualification> is optional. The C chart is used for Poisson counts. For the Poisson counts case, you can have either an area of material that is being inspected or a sample size. The C chart is used when the sub-groups have constant area (or equal sample size).

where <y> is the response variable containing the number of defectives for each sub-group; <area> is a variable containing the sample size or area adjustment for each sub-group; <x> is a variable containing the sub-group identifications; and where the <SUBSET/EXCEPT/FOR qualification> is optional. The U chart is used for Poisson counts. For the Poisson counts case, you can have either an area of material that is being inspected or a sample size. The U chart is used when the sub-groups have unequal area (or unequal sample size).

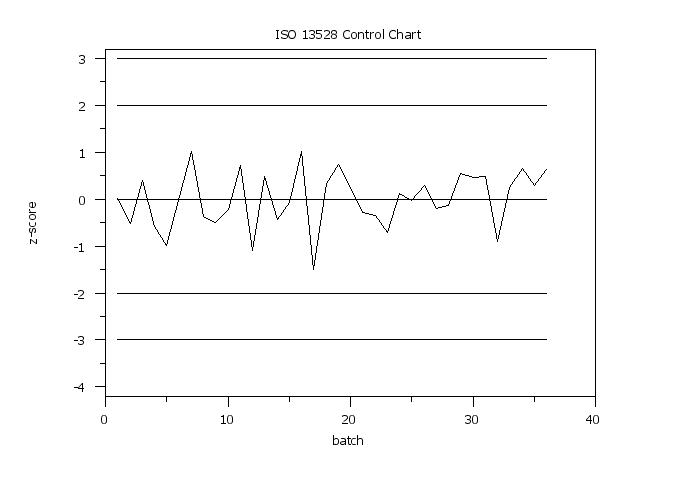

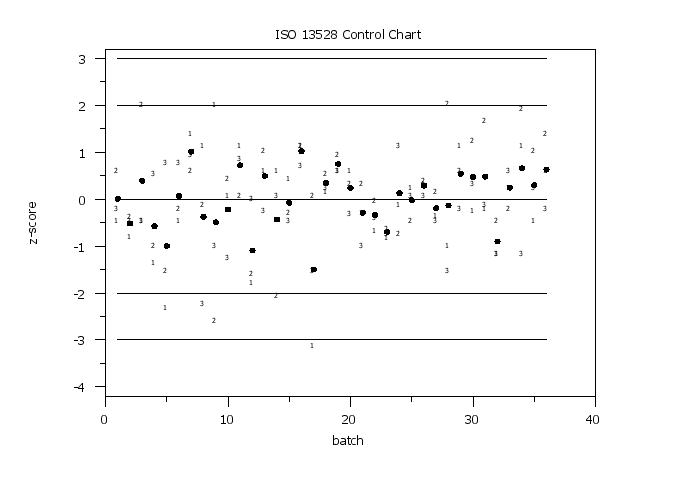

where <y> is the response variable; <x> is a variable containing the sub-group identifications; and where the <SUBSET/EXCEPT/FOR qualification> is optional. This is a variant of the mean control chart. This chart is constructed as follows:

For the ISO 13528 control chart, the sub-groups are typically the different laboratories. The ISO 13528 control chart is used to identify laboratories that are not consistent with the other laboratories in the proficiency study.

RANGE CONTROL CHART Y X S CONTROL CHART Y X MOVING AVERAGE CONTROL CHART Y X

One of the motivations for control charts is to detect problems during production rather than after production. That is, if a production problem can be detected early, then this can help minimize the number of defective units produced.

LET USL = <value> LET LSL = <value> This sets the target value, the upper control limit, and the lower control limit respectively.

For example, some analysts prefer to draw the value of the statistic as a character or spike rather than a connected line. If you include both Dataplot calculated and user-specified limits, you may want to draw them with different colors or different line styles. For the other control charts, the documentation for the specific control charts provides a similar listing for the mapping of traces to chart features. These may vary somewhat from the above list.

The HOTELLING CONTROL CHART can be used to simultaneously monitor multiple response variables for a shift in location. Although you can monitor multiple response variables with individual mean control charts, this assumes that the response variables are independent. The Hotelling control chart takes the correlation structure into account.

The command

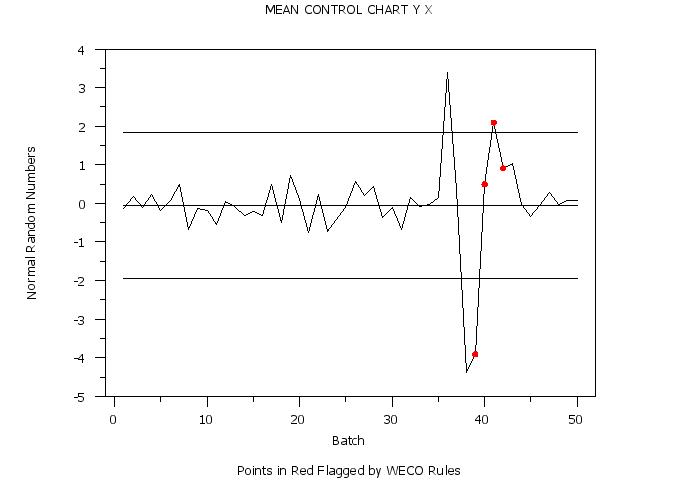

can be used to specify the control limits used. DEFAULT uses the standard control chart limits. WECO uses the Western Electric guidlines. ISO 13528 uses the +/-2 and +/-3 limits (this assumes the response variable has been transformed to a z-score). Note that the if the WECO rules are turned on, the following is done:

The WECO rules have been criticized for generating too many false positives.

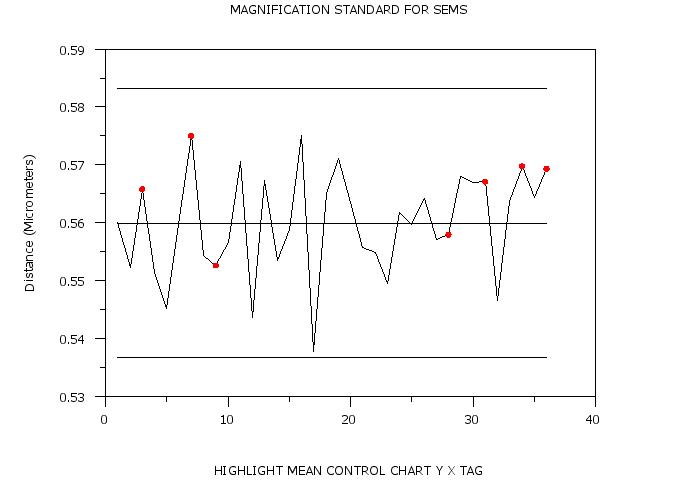

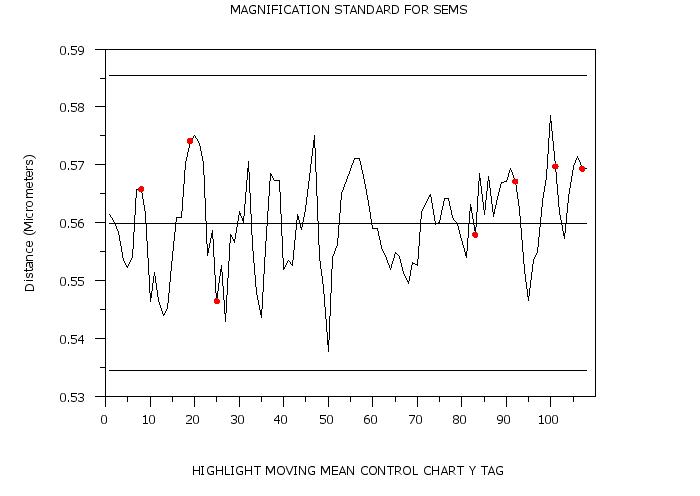

The 2012/02 version added the HIGHLIGHT option. This is demonstrated in the Program 2 example below.

STANDARD DEVIATION CONTROL CHART for S CONTROL CHART

Kaoru Ishikawa (1982), "Guide to Quality Control," Asian Productivity Organization, (Chapter 7). Thomas Ryan (1989), "Statistical Methods for Quality Improvement", Wiley. Douglas Montgomery (2001), "Introduction to Statistical Quality Control", Fourth Edition, Wiley. ISO 13528 (2005), "Statistical Methods for use in proficiency testing by interlaboratory comparisons," First Edition, 2005-09-01.

1988/01: Support for P, PN, U, and C charts 1990/07: Support for user specified control limits 1997/03: Support for CUSUM and EWMA charts 1997/03: Support for moving average, moving range and moving sd charts 2012/01: Support for highlighting option 2012/01: Support for WECO and ISO 13528 control limits 2012/02: Support for ISO 13528 control chart

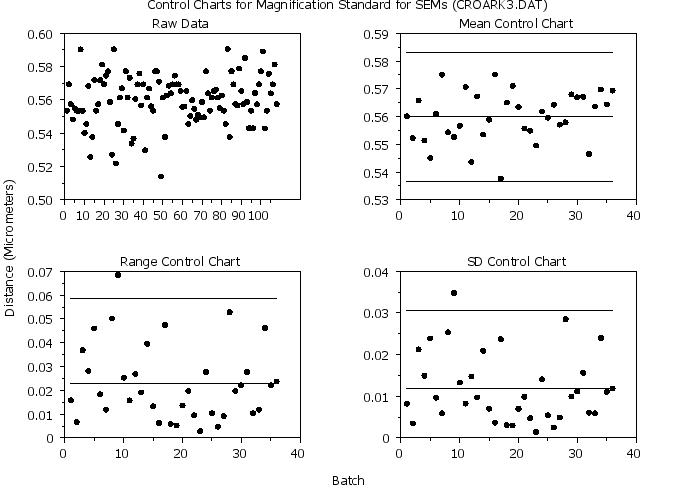

SKIP 25

READ CROARK3.DAT Y X

.

MULTIPLOT CORNER COORDINATES 2 2 98 98

MULTIPLOT SCALE FACTOR 2

MULTIPLOT 2 2

TITLE CASE ASIS

CASE ASIS

TITLE OFFSET 2

LINE BLANK SOLID DASH DASH DOTT DOTT

CHARACTER CIRCLE

CHARACTER FILL ON

CHARACTER HW 1 0.75

.

YLIMIT 0.5 0.6

MAJOR YTIC MARK NUMBER 6

Y1TIC MARK LABEL DECIMAL 2

XLIMITS 0 100

X1TIC MARK OFFSET 0 20

TITLE Raw Data

PLOT Y

.

YLIMIT

MAJOR YTIC MARK NUMBER

Y1TIC MARK LABEL DECIMAL

XLIMITS 0 40

X1TIC MARK OFFSET 0 0

TITLE Mean Control Chart

MEAN CONTROL CHART Y X

.

TITLE Range Control Chart

RANGE CONTROL CHART Y X

.

TITLE SD Control Chart

STANDARD DEVIATION CONTROL CHART Y X

.

END OF MULTIPLOT

MOVE 50 98

JUSTIFICATION CENTER

TEXT Control Charts for Magnification Standard for SEMs (CROARK3.DAT)

MOVE 50 2

TEXT Batch

DIRECTION VERTICAL

MOVE 2 50

TEXT Distance (Micrometers)

DIRECTION HORIZONTAL

Program 2:

Program 2:

SKIP 25 READ CROARK3.DAT Y X LET N = SIZE Y LET TAG = 0 FOR I = 1 1 N LET TAG = 1 SUBSET Y > 0.58 . SET WRITE DECIMALS 3 LABEL CASE ASIS CASE ASIS TITLE Magnification Standard for SEMs Y1LABEL Distance (Micrometers) XLIMITS 0 40 X3LABEL AUTOMATIC LINE SOLID SOLID DASH DASH BLANK CHARACTER BLANK BLANK BLANK BLANK CIRCLE CHARACTER FILL ON ALL CHARACTER HW 1 0.75 ALL CHARACTER COLOR RED ALL . HIGHLIGHT MEAN CONTROL CHART Y X TAG .

LET TAG = 0 FOR I = 1 1 N

LET TAG = 1 SUBSET Y > 0.58

LIMITS

XLIMITS 0 100

XTIC MARK OFFSET 0 10

HIGHLIGHT MOVING MEAN CONTROL CHART Y TAG

Program 3:

Program 3:

LET X = SEQUENCE 1 10 1 50

LET Y = NORMAL RANDOM NUMBERS FOR I = 1 1 500

LET Y2 = Y

LET Y2 = 7*Y FOR I = 351 1 425

LET Y = Y2

.

SET WRITE DECIMALS 3

LABEL CASE ASIS

CASE ASIS

Y1LABEL Normal Random Numbers

TITLE AUTOMATIC

LINE SOLID SOLID DASH DASH BLANK

CHARACTER BL BL BL BL CIRCLE

CHARACTER FILL ON ALL

CHARACTER HW 0.5 0.375 ALL

CHARACTER COLOR RED ALL

XLIMITS 0 50

XTIC MARK OFFSET 1 2

.

SET CONTROL CHART LIMITS WECO

MEAN CONTROL CHART Y X

Program 4:

Program 4:

skip 25

read croark3.dat y roundid

skip 0

let n = size y

. let z = zscore y roundid

let z = zscore y

let matid = sequence 1 1 3 for i = 1 1 n

.

label case asis

y1label z-score

x1label batch

xlimits 0 35

x1tic mark offset 0 2

y1tic mark offset 0.2 0.2

title case asis

title offset 2

title ISO 13528 Control Chart

line solid solid dash dash dash dash blank

character blank blank blank blank blank blank blank

character hw 1 0.75 all

character fill on all

.

iso 13528 control chart z roundid

.

line blank solid dash dash dash dash blank blank blank

character circl blank blank blank blank blank 1 2 3

highlight iso 13528 control chart z roundid matid

Program 5:

Program 5:

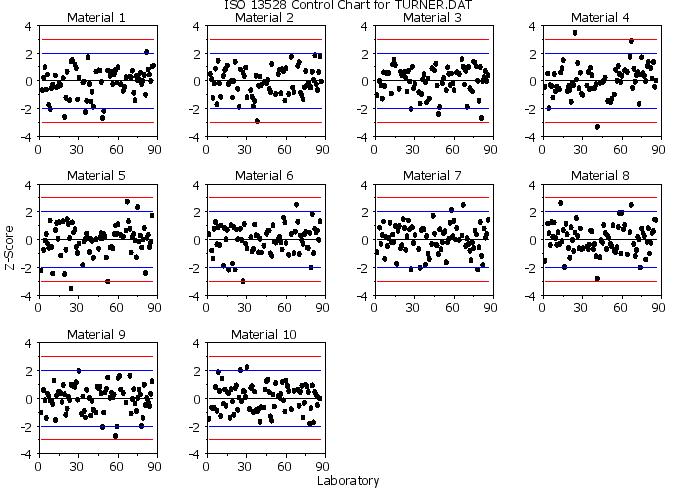

. Read data: Year is essentially the round and there are 10

. materials.

skip 25

read turner.dat labid z year quart matid matave

skip 0

.

. Note that we want to generate the control chart treating

. laboratory as the "group-id" variable. Generate a separate

. plot for each material.

.

case asis

label case asis

title case asis

title offset 2

line blank solid solid solid solid solid blank

line color black black blue blue red red black

character circle blank blank blank blank blank blank

character hw 1 0.75 all

character fill on all

.

multiplot corner coordinates 2 2 98 98

multiplot scale factor 3

multiplot 3 4

.

xlimits 0 90

major xtic mark number 4

ylimits -4 4

major ytic mark number 5

let nmat = unique matid

loop for k = 1 1 nmat

title Material ^k

iso 13528 control chart z labid subset matid k

end of loop

end of multiplot

.

justification center

move 50 98

text ISO 13528 Control Chart for TURNER.DAT

move 50 2

text Laboratory

direction vertical

move 2 50

text Z-Score

Program 6:

Program 6:

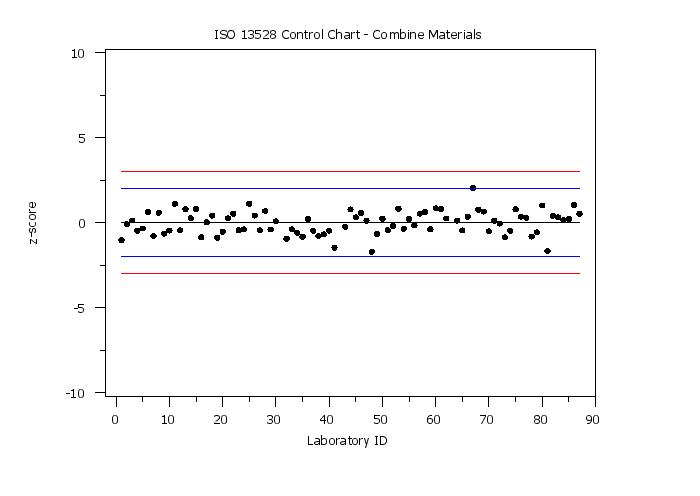

. Step 1: Read the data

.

dimension 40 columns

skip 25

read turner.dat labid z year quarter matid matave

let roundid = year

skip 0

.

. Step 2: Set plot control settings

.

case asis

label case asis

title case asis

title offset 2

.

y1label z-score

x1label Laboratory ID

xlimits 0 90

x1tic mark offset 2 0

ytic mark offset 0.2 0.2

.

line blank solid solid solid solid solid blank

line color black black blue blue red red black

character circle blank blank blank blank blank blank

character hw 1 0.75

character fill on

.

. Step 3: Generate 13528 Control Charts

.

title ISO 13528 Control Chart - Combine Materials

iso 13528 control chart z labid

.

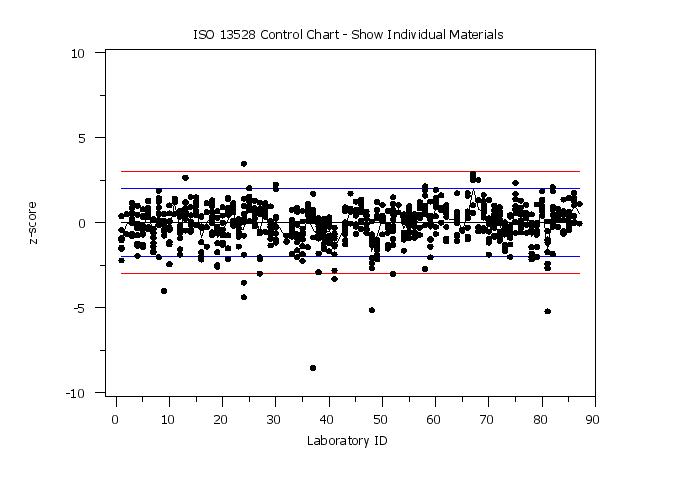

line solid solid dash dash dash dash blank

character blank blank blank blank blank blank circle

title ISO 13528 Control Chart - Show Individual Materials

iso 13528 control chart z labid

.

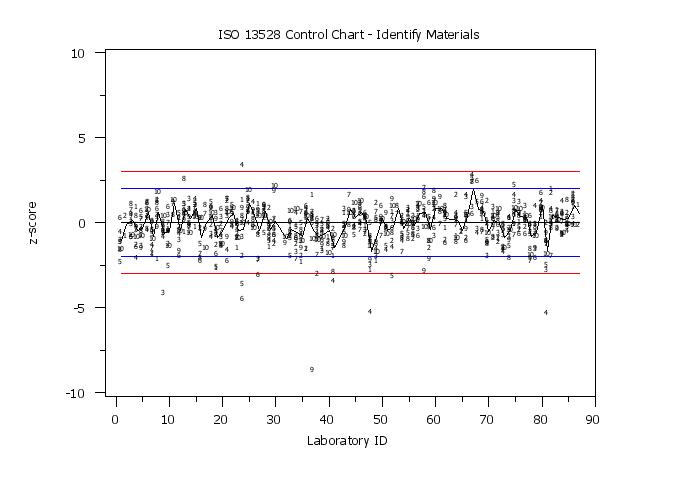

line blank all

line solid solid dash dash dash dash

character blank blank blank blank blank blank 1 2 3 4 5 6 7 8 9 10

title ISO 13528 Control Chart - Identify Materials

highlight iso 13528 control chart z labid matid

Date created: 02/10/2015 |

Last updated: 12/04/2023 Please email comments on this WWW page to [email protected]. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||