SINGLE SAMPLE ACCEPTANCE PLAN

Name:

SINGLE SAMPLE ACCEPTANCE PLAN

Type:

Purpose:

Generates a single sample acceptance plan.

Description:

A lot acceptance sampling plan is a sampling scheme and a

set of rules for making decisions. The decision, based on

counting the number of defectives in a sample, can be to

accept the lot, reject the lot, or to take another sample.

For a single sampling plan, one sample of items is selected

at random from a lot and the disposition of the lot is

determined from the resulting information. These plans are

also denoted as (n,c) plans since there are n observations

and the lot is rejected if there are more than c defectives.

Single sample acceptance plans are the most common and

easiest plans to use. However, they are not the most

efficient in terms of the average number of samples needed.

The input to this command is the following four parameters:

- P1 = the acceptable quality level (AQL). The AQL is the

a proportion defective that is the base line requirement

for the quality of the producer's product. The producer

would like to design a sampling plan such that there

is a high probability of accepting a lot that has a

defect level less than or equal to the AQL. In Dataplot,

this value should be entered as a proportion (i.e.,

a value between 0 and 1.0).

- P2 = the lot tolerance percent defective (LTPD). The

LTPD is a designated high defect level that would be

unacceptable to the consumer. The consumer would like

the sampling plan to have a low probability of accepting

a lot with a defect level as high as the LTPD. In

Dataplot, this value should be entered as a proportion

(i.e., a value between 0 and 1.0).

- ALPHA = the Type I Error (Producers Risk). This is the

probability, for a given (n,c) sampling plan, of

rejecting a lot that has a defect level equal to the

AQL. The producer suffers when this occurs because a

lot with acceptable was rejected. Typical values for

ALPHA range from 0.2 to 0.01.

- BETA = the Type II Error (Consumers Risk). This is the

probability, for a given (n,c) sampling plan, of

accepting a lot with a defect level equal to the

LTPD. The consumer suffers when this occurs because

a lot with unacceptable quality was accepted. Typical

values for BETA range from 0.2 to 0.01.

The output is the following two numbers:

- N = the size sample to collect.

- C = reject the lot if this number of defectives exceeded.

Syntax:

SINGLE SAMPLE ACCEPTANCE PLAN <p1> <p2>

<alpha> <beta>

where <p1>is a number or parameter that specifies the AQL;

<p2>is a number of parameter that specifies the LTPD;

<alpha> is a number or parameter that is the producers

risk;

and where <beta> is a number or parameter that is the

consumers risk.

Examples:

SINGLE SAMPLE ACCEPTANCE PLAN 0.98 0.05 0.01 0.10

LET P1 = 0.98

LET P2 = 0.05

LET ALPHA = 0.01

LET BETA = 0.10

SINGLE SAMPLE ACCEPTANCE PLAN P1 P2 ALPHA BETA

Note:

In addition to printing the values of N and C, Dataplot

stores these values in the internal parameters SSN and

SSNC. These parameters can be used in subsequent Dataplot

analysis if needed.

Note:

Default:

Synonyms:

Related Commands:

|

CONTROL CHART

|

= Generate various types of control charts.

|

|

CP

|

= Compute a Cp capability index.

|

|

CUSUM ARL

|

= Generate a cusum average run length chart.

|

Reference:

Douglas Montgomery (1981), "Introduction to Statistical Quality

Control," John Wiley, 1991.

Applications:

Implementation Date:

Program:

LET P1 = 0.01

LET P2 = 0.05

LET ALPHA = 0.05

LET BETA = 0.10

SINGLE SAMPLE ACCEPTANCE PLAN P1 P2 ALPHA BETA

.

LET N = SSN

LET C = SSC

.

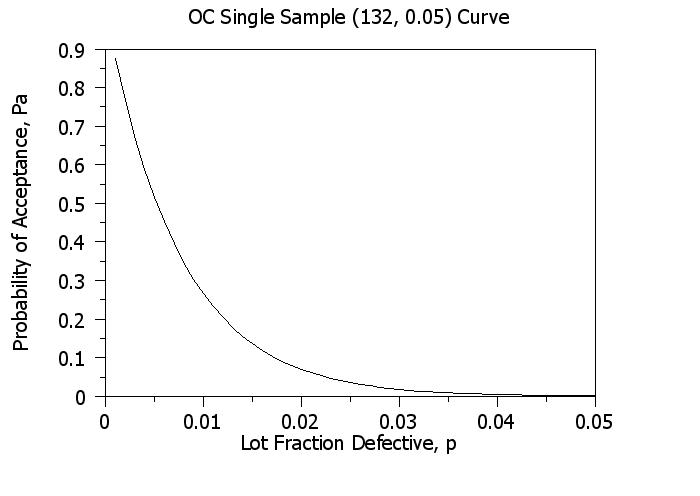

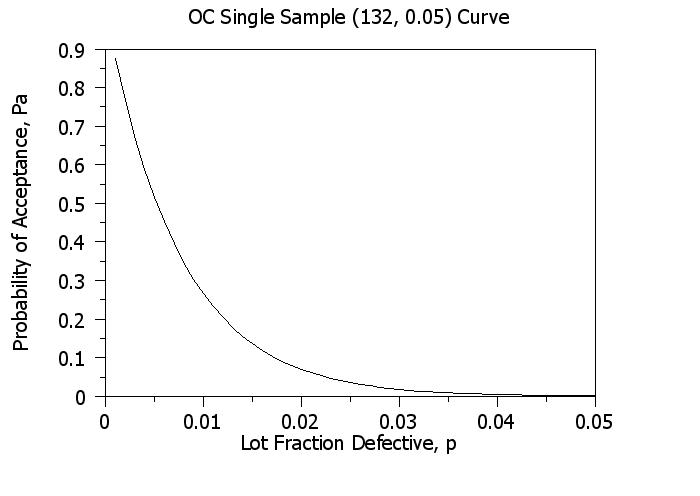

. Purpose--Generate an Operating Characteristic curve for a

. single sample plan. The OC is defined as:

. BINCDF(c,p,n) versus p

. where

. n = sample size

. c = acceptance number for defectives

. p = desired binomial probabilities

.

LABEL CASE ASIS

TITLE CASE ASIS

Y1LABEL Probability of Acceptance, Pa

X1LABEL Lot Fraction Defective, p

TITLE OC Single Sample (^SSN, ^SSC) Curve

.

PLOT BINCDF(SSC,P,SSN) FOR P = 0.001 0.001 0.05

Date created: 06/05/2001

Last updated: 12/11/2023

Please email comments on this WWW page to

[email protected].

|

|